Lithium- Iron batteries can be formed into 3 shapes in general, and each one of them has its advantages and disadvantages. You might have seen one or two of them.

Thanks to the new generation of lithium technologies, manufacturers can form and shape the lithium-iron batteries into a shape of a button known as Coin cells, a Prismatic that looks like a brick, a Polymer, or a Pouch Cells, and a Cylindrical Cell.

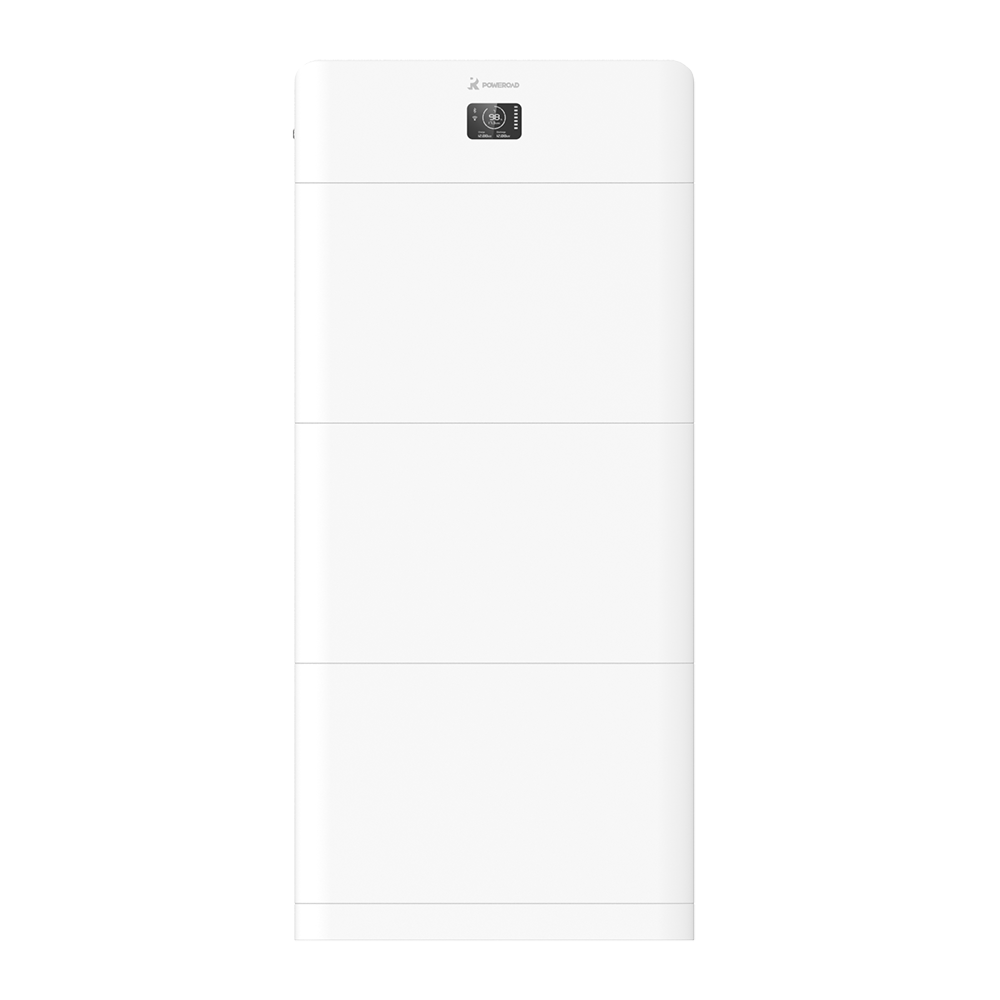

Prismatic Cells

Prismatic Cells

Prismatic Cells were invented in the early 1990s, and the electrochemical materials are sealed into a solid, welded aluminum or steel external case or any form of "metal container." An insulation film covers the exterior, and typically, the film is blue.

There are only a few standard sizes on the market. In general, the names are based on the thickness, width, and length of the batteries.

Due to the square shape of the exterior casing, the Prismatic Cells have a low-profile design, and it improves the volume utilization inside the battery packs. Even though it looks dull, this kind of battery cell could be costly to produce.

Nowadays, Prismatic Cells technology has been applied to various applications, such as Hybrids / Electric Vehicles or DIY Lithium battery banks.

Pouch / Polymer Cells

Lithium-Iron Pouch Cells, also known as Polymer cells, joined the battery game around 1995. They have a similar construction with the Prismatic cells but differently. The cells are sealed into a piece of the foil pouch, and their electrolyte flexibility makes them easy to be produced. The profile size is small and more compact, power delivery and efficiency are usually higher than the other cells.

However, it is more vulnerable than other forms of battery cells, and penetration could cause fire or explosions in the batteries due to the excellent energy density and compact size.

The Pouch Cells are popular among the high-end technology industry and portable applications, such as mobile devices, portable energy stations, drones, etc.

Curved polymer cells tend to be used in wearable consumer and medical devices, whereas the large format polymer cells are used in Energy Storage Systems (ESS) applications and electric and hybrid vehicles.

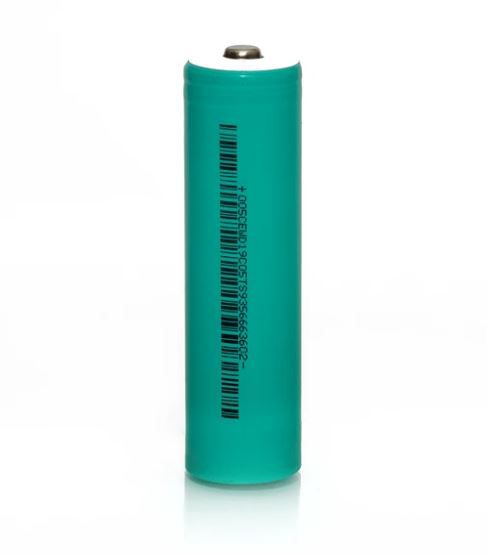

Cylindrical Cells

Cylindrical Cell is the most commonly used battery. When one thinks about batteries, one feels about cylindrical-shaped batteries.

The cells are enclosed in a metal can named based on the diameter and length of the body. For the Lithium-iron batteries, the most common size is the 18650, which refers to 18mm diameter, 65mm length. Some others are like 26650, 21700, etc.

The cylindrical cell is extremely versatile and the preferred choice for multi-cell configurations commonly used in applications such as medical, military, consumer, industrial, EV, and more.

Choose the right provider for your power supply.

CATL, as one of the biggest Lithium-Iron battery cell suppliers around the world, has been providing high-quality battery cells to the global market. Poweroad has been working closely with CATL, selecting the best battery cells for your customization. We can help you customize your battery cells with world-class laser welding technology with various ports, such as the standard M6 and M8 electrode ports.

Quality control has been one of the most severe topics in the electric-related industry. We take it so seriously that you might not be able to imagine that every single piece of the Poweroad productions will be sent to one of the most rigorous tests before any production is happened and packed. You just need to tell us what is in your mind. The rest of your brilliant plan will be fulfilled by Poweroad.