There is no doubt the fact that more and more RV users and Marine Boat users are adding lithium-ion phosphate batteries to their mobile power system to store solar energy or shore power to provide a sustained power delivery. One of the top drivers behind the recent growth in the lithium-ion solar battery market has been the rise of Closed-Loop communication between the batteries and the inverters.

Opened-Loop Communication

Most batteries in the market only support Opened-Loop Communication, which means the BMSs of the batteries are unable to send and receive data, it doesn't allow the BMSs to "Talk" to the inverters. In Opened-loop communication, the inverter/charger can only calculate the SoC in a way that detects the voltage of the batteries. Other than the voltage, there is no other information transferred between the inverter/charger and batteries.

As mentioned above, the inverter detects the voltage of the batteries and calculates the State of Charge. Considering there are so many SoC calculation algorithms, the opened-loop communication is not accurate enough to get a realistic result, since it is only the basic method. The Opened-loop communication results in an incorrect State of Charge. For example, the SoC indication on the inverter could be 50% while the real battery SoC is 30%, and the limitation is obvious.

Recalibration may help correct the SoC calculation of the inverter/charger, but it is just a temporary fix, imagine you must repeat the calibration again and again in the 10-year run time of the batteries.

Closed-Loop Communication

Commonly speaking, Closed-Loop Communication is the process of receiving and confirming information between batteries and inverter/charger. In other words, the loop of communication is closed, in comparison, in Opened-Loop Communication, the information can only be sent and received, but not confirmed.

The form of Closed-Loop Communication is kind of like the early radio interactions. Sending shortcodes like “low voltage”, “start charging” and “roger”, but there are several specific codes to close the loop, for example, “over”, “roger” and so on.

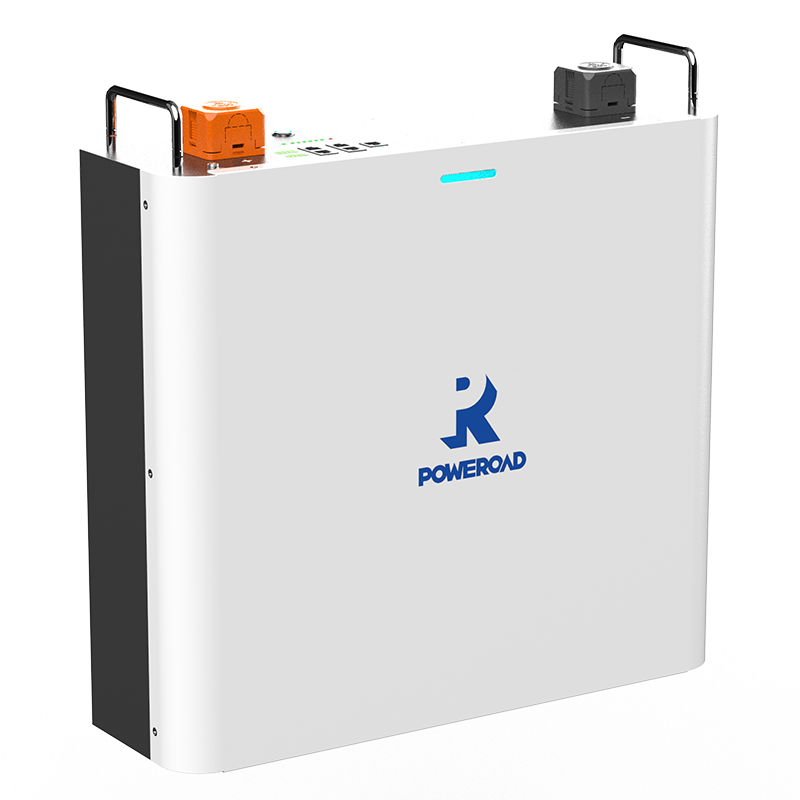

We equipped RS485 and CANBUS protocols to the POWEROAD PRLC LiFePO4 Batteries, enabling Closed-Loop Communication within the battery bank and inverter, the batteries not only communicate with each individual in the battery bank but also with the inverter, sharing SoC information seamlessly. With RS485 and CANBUS supported, the installer can connect the battery bank with the inverter/charger via either communication port that is required, achieving a more intelligent and efficient charging and discharging working environment.

Why is Closed-Loop Communication Important to Off-Grid Solar Battery System?

Closed-Loop communication allows the BMSs to send actual battery information to the inverter/charger so that the inverter/charger would know the accurate SoC (State of Charge) of the batteries, avoiding over-charged and over-discharged, reducing unnecessary charge, enabling an extended battery life, giving the whole system an operating environment to work efficiently.

On the other hand, Closed-Loop Communication also helps the installation to achieve faster and easier.

By enabling communication between batteries and inverter/charger, the energy system will be safer, more efficient, and more reliable.